Ceramic brake pads are known for their quietness, create less visible dust and typically last longer than any organic or semi-metallic alternatives. Yes, they do cost little more and are fragile when used under extreme heat, heavy towing or track use. it has its own pros and cons which we are going to explore in this post.

What they are Ceramic pads?

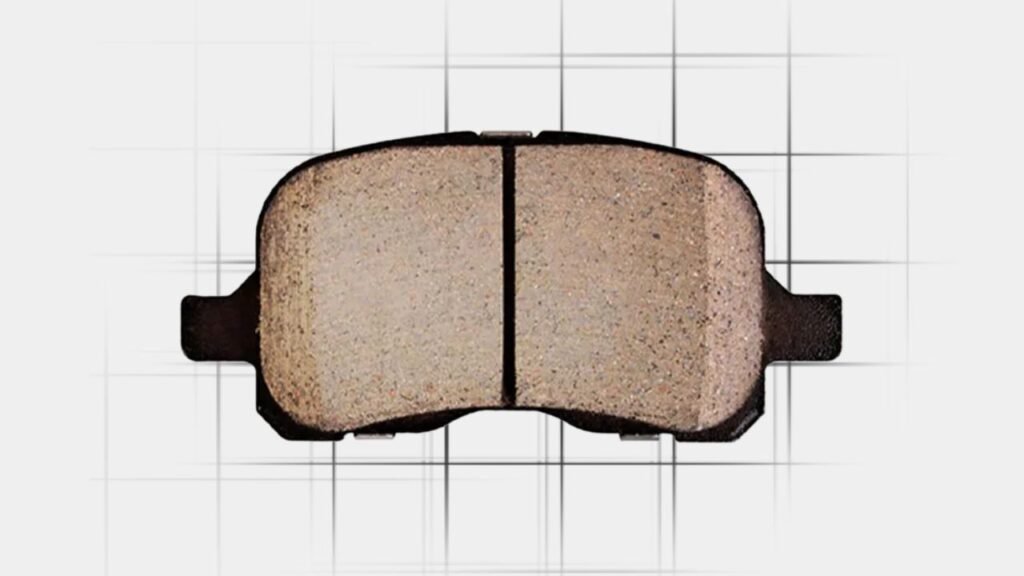

Ceramic pads are similar to pottery ceramics but has added fillers and fibers to create friction. Historically, manufacturers have used copper but nowadays to make it environment friendly most of them are copper-free formulations. Ceramic pads are made to provide optimum friction while on typical street temperature and minimize the noise and dust.

They works by transferring a thin film to the rotor which smoothen out the engagement. since they have lower thermal conductivity than semi-metallic pads the rotor absorbs most of the braking heat during longer stops.

Ceramic Brake Pads Pros and Cons

Ceramic Pads Pros

- Quiet operation: When compared to semi-metallic pads, Ceramic pads have shown to reduce more sequel and grinding.

- Low, light‑colored dust: This is my favorite plus point of Ceramic pads which produces much less visible dust while keeping wheels cleaner.

- Long service life: If you are normal commuter who does not any kind of harsh driving then these are outstanding and let me tell you it has much more life than semi-metallic pads.

- Consistent friction: Performance wise they are just better having stable, predictable braking performance across street driving temperature.

- Rotor friendliness (street use): Typically less abrasive than semi‑metallic pads, helping maintain rotor surface finish in everyday driving.

Ceramic Pads Cons

- Higher price: Material and manufacturing costs are typically above organic and many semi‑metallic options.

- Not ideal for extremes: Semi‑metallic pads generally provide better initial bite in very cold conditions and superior fade resistance under repeated high‑energy stops, towing, mountain descents, or track days.

- Heat management trade‑off: Because the pad absorbs less heat, more energy goes into the rotor and surrounding hardware during heavy use, which can increase rotor temperatures and, in aggressive conditions, rotor wear or brake odor.

- Longer warmup in harsh cold: Some formulations have slightly muted first‑stop bite in sub‑freezing temperatures until a bit of heat builds.

Who should avoid Ceramic Pads?

- Heavy vehicles that regularly tow or carry loads: Quality semi‑metallic pads usually handle heat and repeated stops better.

- Spirited mountain driving or occasional track/autocross: Performance semi‑metallic or specialty track compounds offer higher maximum operating temperatures and stronger high‑speed bite.

- Severe winter climates demanding strong cold initial bite: Certain semi‑metallic or winter‑optimized compounds may feel more responsive on first application.